Plastics Fabrication and Manufacturing Services

Collins Plastics was established in 1983 to Thermoform Acrylic sheets. In the past 35 years the company has diversified to become one of Ireland’s largest plastic sheet fabricators.

We have always invested in the most modern machinery available. Some of the techniques we use are as follows:

Moulding: Thermoforming, Vacuum Forming, Membrane Pressing, Line Bending, Blow Moulding.

Cutting: Panel saw cutting, computerised Beam saw cutting, computerised Laser cutting, CNC cutting.

Polishing & Finishing: Diamond polishing, Flame polishing, Buff finish.

Printing: Screen printing, Flat Bed printing, Vinyl decals.

All parts are then brought to assembly for gluing, welding, vinyl application, and inserts can be applied before inspection and dispatch.

Thermoforming

Thermoforming

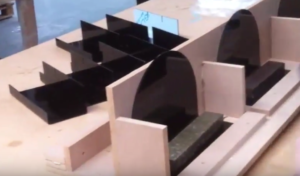

Thermoforming is the technique where we place a sheet in our industrial oven to soften the sheet, different temperatures and times are required for different materials.

When the sheet is soft we place it over the female mould and clamp it to prevent movement.

We then bring down the male part of the mould to press out the shape required.

After the sheet has cooled it can be taken out of the mould and brought to the band saw to be split and then off to trimming before it goes to the next process.

Click here to view a short video

Materials : Acrylic (Perspex), PETG, PET, light Polycarbonate and Foam PVC

Vacuum Forming

Vacuum Forming is the technique where a sheet is clamped in position over a mould, then the heating element is placed over it to soften it.

When the sheet is soft enough a single part mould is driven into the sheet and the air around the mould is sucked into the tanks. This suction draws the sheet on to the mould giving it its shape.

After Thermoforming when the sheet is cooled, it goes to the band saw and routers for trimming and finishing.

Click here to view a short video

Materials : Acrylic (Perspex), Acrylic capped ABS, Styrene, PETG, Foamex and Polycarbonate

Membrane Pressing

Membrane Pressing

Membrane pressing is the technique where we soften a sheet in the industrial oven when the sheet is soft enough we place it over a mould, no clamping is required when membrane pressing.

When the sheet is in position the membrane is brought down over it and the vacuum pump applied to bring the sheet down on to the mould. It is best leave the membrane in position for approx. 30 minutes to make sure the sheet has cooled.

These parts are cut before going into the oven so they don’t go to trimming after moulding. Because we have a special oven attached to our membrane press we can use it separately and can use it for drape forming also.

This technique can give very interesting shapes and profiles.

Click here to view a short video

Materials : Corian, Acrylic(Perspex), PETG, Lexan, Foam PVC, Polystyrene, High Impact Polystyrene (HIPPS), Acrylic capped ABS

Blow Moulding

Blow Moulding

Blow moulding is the technique of blowing domes and rooflights. We take sheets of Acrylic (Perspex), PETG, Foamex, etc. and place them in the oven to soften them, then we put them into a mould made to the size required, dome or rooflight.

When the panel is in position and all is lined up we attach the air line, this blows the dome to the required shape. This is often called free blowing because you can judge the height you like by using your eye, this is where the craft men come in, no computers for this part of the work we do, this is down to our skilled trades men.

Materials: Acrylic (Perspex) Acrylic capped ABS, PET, PETG, Foamex, Polystyrene.

Panel Saw Cutting

Panel Saw Cutting

Panel Saw Cutting is used when we have small sheets and sometimes panels that need to be cut down a bit smaller before going to assembly.

It is commonly used to break down sheets or take a small part off a sheet.

Sometimes a sheet can go to the panel saw that is simply to small to take to the beam saw.

Generally used for small runs or trimming sheets.

Materials : Polycarbonate, Multi-wall Polycarbonate, Acrylic (Perspex) Acrylic capped ABS, Styrene, Foamex, PET, PETG, PP, PE, Polystyrene almost any plastic sheeting.

Computerised Beam Saw Cutting

Computerised Beam Saw Cutting

Computerised Beam Saw Cutting is used where accuracy is very important.

This saw will cut a bank of sheets at the same time with exceptional accuracy. When using this saw, production work is made simple ( this machine can do a weeks work for one person in 2/3 hrs.

The 3 metre sheets are placed into the front of the saw and the dimensions required put into the computer screen.

The sheets are then clamped in to position and drawn back for a trim line cut, then brought forward for the first cut line – whatever dimension that was put into the computer – this saw can cut 3 metre sheets by 90mm thick.

Materials : Polycarbonate, Multi-wall Polycarbonate, Acrylic (Perspex) Acrylic capped ABS, Styrene, Foamex, PET, PETG, PP, PE, Polystyrene almost any plastic sheeting.

Laser Engraving & Cutting

Laser Engraving & Cutting

Laser Cutting involves cutting plastic sheeting without touching the sheet. A laser beam is sent through the sheet and it cuts right through it giving whatever design required.

The shape is drawn on computer in an AutoCAD package or Signlab for sign work. These shapes are sent to the laser and the process begins. Because there isn’t any friction between the sheet and the laser the dimensions cut are very accurate.

When cutting clear Acrylic the laser polishes the edges giving a perfectly finished profile first time. This eliminates any finishing process. Our machine is a 3mt. x 2mt. Eurolaser (Germany) and has 200w power. This means we can cut full size sheets 20mm thick in one pass with a polished finish.

When cutting clear Acrylic the laser polishes the edges giving a perfectly finished profile first time. This eliminates any finishing process. Our machine is a 3mt. x 2mt. Eurolaser (Germany) and has 200w power. This means we can cut full size sheets 20mm thick in one pass with a polished finish.

Materials: clear and coloured Acrylic.

Polycarbonate or other plastic sheets cannot be cut on the laser, while it will cut it will destroy the sheet. Laser is just for Acrylic (Perspex) sheets.

CNC Router Cutting

CNC Router Cutting

CNC Router Cutting is a similar technique as laser cutting. You draw what you would like cut on AutoCAD or Signlab, send it to the router to follow the required profile.

The cutter starts on the top of the sheet and works its way through the sheet.

On lighter sheets we sometimes cut the sheet on the first pass, on thicker sheets we have to use what’s called a multipass. This is when we are cutting a sheet from 10mm up to 50mm. we take a number of passes to go through the sheet possibly 5mm passes.

On lighter sheets we sometimes cut the sheet on the first pass, on thicker sheets we have to use what’s called a multipass. This is when we are cutting a sheet from 10mm up to 50mm. we take a number of passes to go through the sheet possibly 5mm passes.

We have 4 – 3mt. x 2mt. AXYZ automation router beds with twin heads on each. We also use these machines to mill down large sheets and to create shadow boards.

Materials : Lexan Polycarbonate, Acrylic (Perspex) Acrylic capped ABS, Styrene, Foam PVC, PETG, PET, PP, PE, etc

Diamond Polishing

Diamond polishing is a technique used to polish acrylic sheets to give a clear edge to the sheets.

Diamond polishing is a technique used to polish acrylic sheets to give a clear edge to the sheets.

When an Acrylic (Perspex) panel is cut on beam saw or router it will have saw marks on the edge. We take these sheets to the diamond polisher to clear these lines.

We have the largest diamond polisher available.

We can polish 90mm thick in one pass. Generally we don’t have many sheets that thick to polish but again we load the machine and polish a full run of sheets at the same time.

Material – it is just for acrylic (Perspex) sheets

Line Bending

Line Bending

Line Bending is the process where we heat a sheet of material just along the line where we want bend it.

The rest of the sheet is left untouched, because we just heat the part we are working on the rest of the sheet remains intact.

Once the sheet is put into position it is locked and can’t move, the heating bars soften just the part we are working on.

When we take the sheet from the Line Bender we can shape it to any angle we need for the specification.

Materials : Acrylic (Perspex), Lexan Polycarbonate, PETG, Foamex, Styrene, PET, Acrylic capped ABS.

Screen Printing

Screen Printing

Using Screen Printing we can print your logo and text directly on to sheets of plastic for displays.

This process is particularly effective for machine guarding or line clearance blocks.

Screen Printing for runs of a few hundred units with just 3 or 4 colours is a very cost effective production process.

Materials : Acrylic (Perspex) Lexan Polycarbonate, Foam PVC, PETG and ABS.

Flatbed Printing

Flatbed Printing is the process where we can print directly on to a sheet of plastic.

The sheet is cut to the shape required and placed on the bed for printing.

It is a more accurate process than screen printing.

This process provides a very good finish and it can be used on a variety of materials. It’s a very good technique for complicated printing.

Materials : Acrylic (Perspex), PETG, Foamex, Acrylic capped ABS.

Vinyl Labelling

Vinyl Labelling

Applying Vinyl is a cost effective way of adding stickers or decals to units.

When the quantity is low, or doesn’t fit in to the category for flat bed printing, it doesn’t justify making a screen for screen printing .

We generally use it for short runs of 20 – 50 units where some print would add to a finished unit.

Materials : Acrylic (Perspex), Styrene, Acrylic capped ABS, PETG, PET and Lexan.